Hydraulic Equipment for Construction Machines (Our Own Design)

Hydraulic equipment for construction machines is mainly used in cranes and aerial work platform vehicles.

At Morikawa Gauge, we design, machine, assemble, and test operate a variety of hydraulic valves to be delivered as finished products.

Our technology can be used to create a variety of compact, lightweight equipment as well as high-pressure equipment.

Multi-Control Valve MX Series

A multi-control valve is a manual switching valve used in construction machinery, industrial machinery, vehicles, and other machinery.

The device features a sandwich construction and can include up to 10 valves.

Each port can operate independently.

The standard port size is G3/8, and the standard pump port and tank port are G1/2.

Composite Valves

Composite valves incorporate multiple valves.

They can combine switching valves, check valves, safety valves, solenoid valves, and other valves.

One valve can have multi-functional control.

The port size can also be adjusted to match the flow rate.

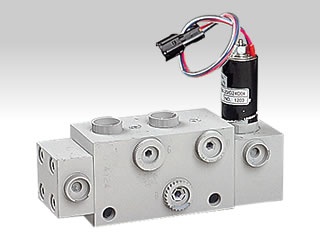

Solenoid Valves

Solenoid valves are electromagnetic switching valves mounted to a plate.

Our solenoid valves have a maximum working pressure of 34.3 MPa (350 kgf/cm2) and a flow rate of 80 l/min, and can be used in construction machinery and machine tools.

These valves are mainly used in machine tools, construction machinery, and special vehicles.

Our solenoid valves conform to ISO 4401-AB-03-4.

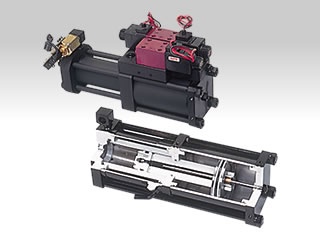

Booster Assemblies

A booster assembly is a booster that uses the area ratio.

It can boost pressure to a maximum working pressure of 98 MPa (1000 kgf/cm2).

Standard specifications include a pressure increase ratio of 1:5, a secondary side discharge pressure of 70 MPa, and a secondary side discharge flow rate of 160 cm3/stroke.